315

Package Size 82.00cm * 37.00cm * 53.00cm Package Gross Weight 58.000kg RIYANG BUTT FUSION WELDING MACHINE V630 Riyang V

Description

Basic Info.

| Model NO. | V630 |

| Frequency Range | Low Frequency |

| Electric Current | AC |

| Style | Vertical |

| Power | Electric |

| Volume | 3.09m³ |

| Voltage | 380V ( *220V ) |

| Customized | Yes |

| Certificates | CE&ISO |

| Max Pressure | 12MPa |

| Suitable Materials | PP PVC PVDF PE |

| Operation Way | Hydraulic |

| Warranty | 2 Years |

| Product Name | 630mm Plastic Pipe Butt Fusion Welding Machine |

| Transport Package | Plywood Box |

| Specification | 3 plywood boxes |

| Trademark | RIYANG |

| Origin | China |

| HS Code | 8515219900 |

| Production Capacity | 500 Units / Month |

Packaging & Delivery

Package Size 82.00cm * 37.00cm * 53.00cm Package Gross Weight 58.000kgProduct Description

RIYANG BUTT FUSION WELDING MACHINE V630

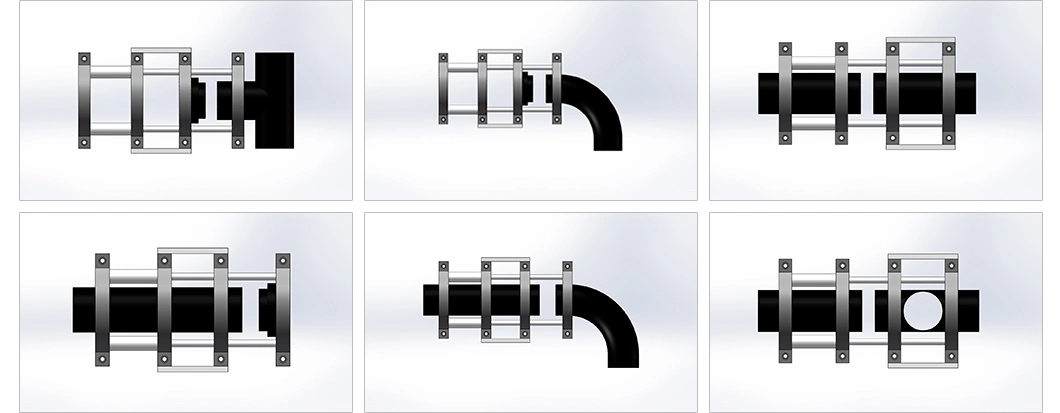

Riyang V series is on-site hydraulic butt fusion welding machine.It is used to butt weld pipe and fittings such elbow, tees, wye and flange necks without any additional equipment by simply adjusting the clamps and drag bar.It is suitable for welding plastic pipe and fittings made of HDPE, PP, PVDF and other thermoplastics material.

| Technical Parameters | V630 |

| Welding Range O.D. | 315-630 mm |

| Power Supply | 380V±10%, 50/60Hz ( * 3 phase, 220V ) |

| Rated Power | 12.3 kw |

| Working Pressure Range | 0-120 bar |

| Piston Area | 23.06 cm2 |

| Temperature Range | Max. 320ºC |

| Packing dimension | 1600*1130*1100 mm |

| 1030*720*1350 mm | |

| 800*350*400 mm | |

| Gross Weight | 739 kgs |

Basic FrameFeatured by - Oil seal kit, origins from Germany, make sure that the pressure performance stays in more stable way.- 4sets quick coupling helps operator to prepare the machine better before and after welding, and we use STUCCHI which from Italy ensures no hydraulic oil leakages when unplug or plug in.- Using integral shaft(top chromate treatment) instead of assembled shaft, ensure the chassis strength to avoid possible frame twist or deform when dragging the pipe with extreme parameters.

Heating PlateFeatured by- We use Dupont from USA for coating of the heating plate, which is the best in industry. It's much sticker to aluminum plate, more non-sticky to plastic pipes surface. Temperature deviation of different points on heating plate is 2-3 degrees (small size machine) and 5-6 degree (big size machine). Trimmer featured by- High-quality drill, which can do 220V, 3phase as option.Electrical box Assy.featured by- Temperature-controlled switchWhen temperature-controlled switch is off, all the aviation plugs are not live, even the power cable connected with the power source. It is quite safe to connect or disconnect the plugs before or after welding.- Very well-connected wires and more reasonable layout. Each wire is marked with the corresponding numbers, thus giving more convenience to do trouble shooting when a failure happens.Supportfeatured by- Ergonomic design Hydraulic Power StationFeatured by- Solid relays have a bigger load capacity and working in more stable situation, which has much longer life.- The circuit breaker works with electricity leadkage protection switch. Including the earth wires, there're 2 elements to activate the protection when electircity is leaking.- Accumulator: Properly adjusting and installing the accumulator could gives much help to cushion the pressure when it is rising and falling. Undoubtedly it can help to keep the pressure stable for welding procedure (soaking, cooling). With the accumulator, the welding procedure will accord with the welding standard of DVS2207-1-2016 and ISO21307-2017

| Stub End Holder | PEWELDBANK Data Logger | MAMBA630 Pipe Support Roller | Lifting Crane |

Q&A:

1. PAYMENT TERMSWe accept 30% TT deposit and 70% balance payment against photo before delivery or 100% TT in advance.2. LEAD TIMEUsually, we have plenty of stock for V355 and below, and keep max. 3units for V450 and V630. As to V800 and above, we'll arrange production according to the actual orders.3. WARRANTY2 YEARS. During the warranty period, RIYANG authorized dealer and RIYANG will totally cover the responsibility to fix the machine; Claim parts usually could be couriered to clients within 3days since receiveing the claim. Express fee will be borned by RIYANG.4. CAN YOU DO CUSTOMIZED DESIGNYES. RIYANG has its own design and technical team that can undertake OEM and ODM, but there are quantity requirements, please contact our sales consultant for more information, thank you.5. CAN YOU PROVIDE TRAINING CLASS ?1. Customers are welcome to come to our factory for 1-2 weeks of training, in addition to air tickets and hotels, RIYANG can afford meals and local transportation costs. 2. We can also arrange for technical personnel to fly to the customer's local to do on-site training, for a period of 1-2 weeks, customers bear air tickets, hotels, catering, as well as technical training fees, please contact our sales consultant for details.3. RIYANG offers online training in English and Spanish, which requires an appointment in advance.6. HOW COULD BE YOUR DISTRIBUTOR AT LOCAL? RIYANG welcomes customers from all over the world to negotiate agency business, but for agents, we have specific requirements, details please contact our sales consultant, thank you!

You may be concerned: V315mm CNC Butt fusion welding machine V160M Plus with Data Logger V1000mm with Crane

Next: 40

Our Contact

Send now